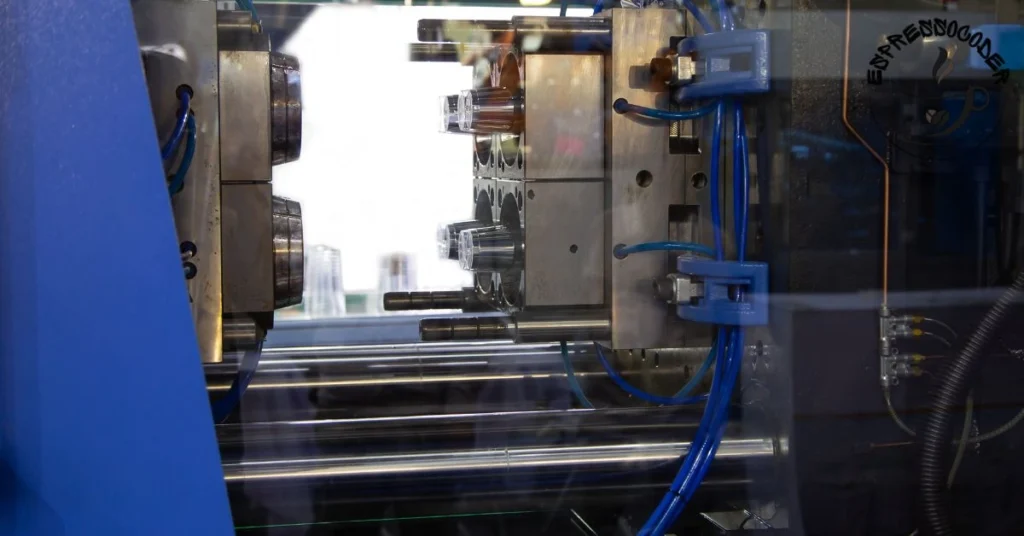

The Cincinnati Milacron CT 110-7 (1996) is a notable injection molding machine in the manufacturing industry. Known for its durability and efficiency, this model has been a reliable choice for many businesses. It offers a clamping force of 110 tons, making it suitable for various applications. Despite being released in 1996, its performance remains competitive today. Manufacturers appreciate its ability to deliver high-quality parts with precision. In this blog post, we will explore the specifications, performance capabilities, advantages, and frequently asked questions about this injection molding machine.

Also read:https://espressocoder.org/make1m-com-luxury-watches/

Technical Specifications and Key Features

Machine Type and Clamping Force

This horizontal injection molding machine is designed for precision in plastic molding. It features a clamping force of 110 tons, ideal for a wide range of molding applications. The strong clamping force ensures that the mold remains tightly closed during the injection process.

Injection Unit

The injection unit of this model is highly efficient. It includes a screw diameter that allows for precise control over the amount of plastic injected into the mold. This machine can handle high injection pressure, making it capable of producing detailed and complex parts. Manufacturers looking for speed and accuracy in production find this feature particularly beneficial.

Power and Energy Consumption

One key feature of this injection molding machine is its energy efficiency. It operates on moderate power levels, making it a cost-effective option for businesses. Even as an older model, its energy consumption remains competitive. This can help manufacturers reduce operational costs over time.

Control System

Equipped with a user-friendly control system, this machine allows operators to monitor and adjust settings easily. Although it may not have the advanced technology of newer models, the system provides essential controls needed for efficient production. Its reliability and straightforwardness make it accessible for operators of all experience levels.

Performance Capabilities

Speed and Efficiency

This machine is known for its high production speed. It offers relatively short cycle times, enabling a large number of parts to be produced quickly. This feature makes it ideal for companies needing to meet high production demands. Even as an older model, its efficiency is still impressive.

Precision and Accuracy

One of its strengths is the ability to deliver high precision during the molding process. It can handle intricate mold designs with tight tolerances, ensuring that every part produced is consistent in size and quality. Businesses that require detailed or complex parts find this feature especially valuable.

Material Compatibility

The machine is compatible with a variety of plastic materials, offering manufacturers flexibility. It can handle both common plastics and specialty materials used in advanced applications. This versatility allows businesses to use the machine for different projects without needing significant adjustments.

Maintenance Needs and Reliability

This injection molding machine is known for its reliability and low maintenance requirements. While regular maintenance is still needed, the machine operates smoothly with minimal issues. Its durable construction contributes to a long lifespan, and with proper care, it can serve manufacturers for many years.

Advantages of Using the 1996 Model Today

Cost-Effectiveness

One of the biggest advantages of this model is its affordability. As an older machine, the initial purchase price is significantly lower than that of newer injection molding machines. This makes it a great option for small to mid-sized companies looking to expand production without breaking the bank. The lower cost doesn’t mean sacrificing quality or performance.

Proven Reliability Over Time

The machine has built a reputation for long-term reliability. Many businesses have successfully used it for decades, attesting to its durability and low downtime. It is designed to handle high-volume production without frequent breakdowns, making it a trusted workhorse in the industry. This reliability translates into reduced maintenance costs and fewer production delays.

Ease of Integration with Modern Systems

Despite being an older model, this injection molding machine can easily be integrated into modern production lines. With minor modifications, it works seamlessly alongside newer machines, making it a versatile option for manufacturers. Companies do not need to completely overhaul their systems to accommodate this model, making it a cost-effective way to increase production capacity.

Parts Availability and Service Support

Many replacement parts for this machine are still readily available, ensuring that businesses can maintain and repair it easily. Additionally, service technicians are well-versed in handling this model, and many companies offer repair and maintenance services. This availability extends the machine’s useful life, making it a solid investment.

Lower Depreciation Rate

Unlike new machines that depreciate quickly, this injection molding machine has already passed its steep depreciation curve. This means it will retain its value over time, which is especially important for businesses looking to resell or upgrade equipment in the future. The lower depreciation also makes it a better long-term investment compared to newer machines.

Energy Efficiency

Despite being an older model, this machine is still considered energy-efficient for its time. Its moderate power requirements help businesses save on electricity costs, especially compared to larger or less efficient machines. While newer models may offer advanced energy-saving features, this model remains a cost-effective option for companies looking to balance performance with energy consumption.

Proven Track Record in Diverse Industries

The machine has been used in a variety of industries, from automotive to packaging and consumer goods. Its versatility and ability to handle different types of plastics make it a reliable choice for businesses working with various materials. This broad industry application speaks to the machine’s adaptability and consistent performance over time, making it a valuable asset for manufacturers in diverse sectors.

Long-Term Value

Overall, this injection molding machine offers excellent long-term value for businesses. It combines affordability, reliability, and ease of maintenance, making it a solid investment. Whether you are a smaller business looking to grow or an established company in need of a reliable addition to your production line, this model continues to hold its own in the industry. Its proven track record and low operating costs ensure that it remains a competitive choice, even decades after its release.

Conclusion

The Cincinnati Milacron CT 110-7 (1996) remains a trusted choice in the injection molding industry, offering businesses a blend of reliability, efficiency, and affordability. Its robust design, combined with a clamping force of 110 tons, enables it to handle a wide range of materials and applications effectively. While it may not feature the latest technology, the machine’s proven performance and low operating costs make it a valuable asset for manufacturers.

With its energy efficiency and ease of maintenance, this model continues to serve companies well, even decades after its release. The availability of replacement parts and service support further enhances its long-term viability. For businesses looking to expand their production capabilities without significant financial investment, the CT 110-7 offers a solid, cost-effective solution that ensures consistent quality and performance.

FAQs

What is the clamping force of this injection molding machine?

The machine has a clamping force of 110 tons, ensuring a firm hold on the mold during the injection process. This is ideal for a variety of plastic molding applications.

Is the machine still energy-efficient?

Yes, despite being an older model, it is still considered energy-efficient for its class. Its moderate power requirements help businesses keep operating costs lower.

Can the machine handle different types of plastics?

Yes, it is compatible with a wide range of plastic materials, making it versatile for different injection molding projects.

Are parts and services still available for this model?

Yes, replacement parts for this injection molding machine are widely available, and many service providers offer repair and maintenance support.

How does this model compare to newer injection molding machines?

While newer models may have advanced features, this machine remains reliable and cost-effective. It is a great option for businesses looking for durability and consistent performance without the higher cost of modern machines.